Multiphase pumping has evolved to become a critical component within the E&P industry in many different production schemes. In this scientific study, it is a means for reducing wellhead pressure on producing wells and consequently increases production and improves ultimate recovery. Within the subject of ‘Enhanced Gas Recovery’ an optimized recovery effect and accelerated production on an existing gas field with 40 years of production history was investigated. The test site Rütenbrock is located in the NW part of Germany and is operated by Wintershall.

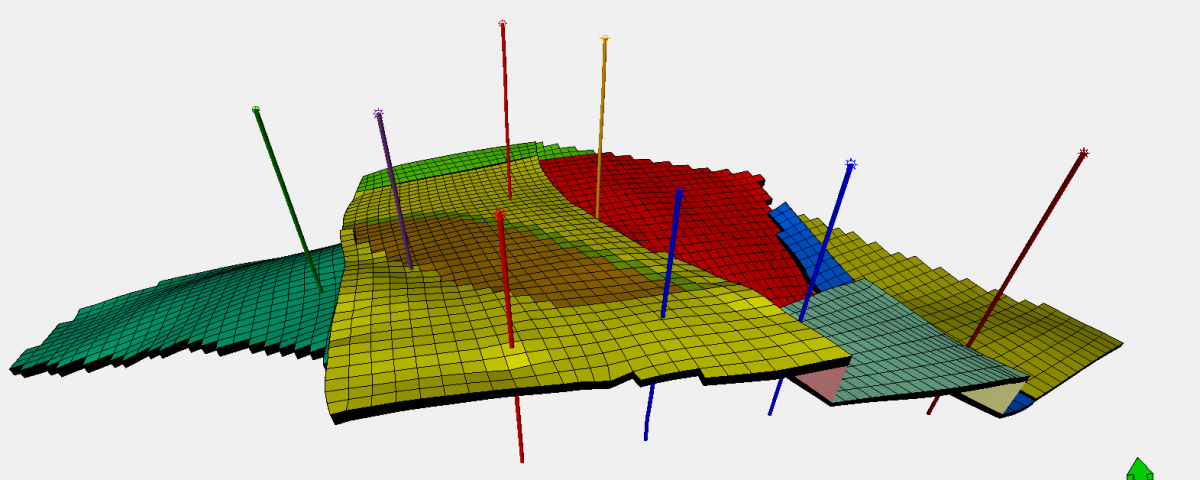

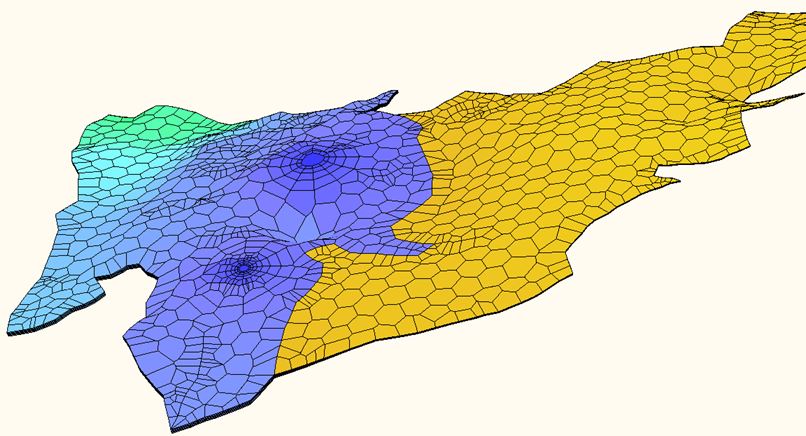

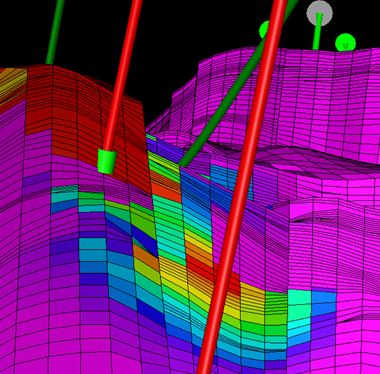

The field Rütenbrock represents the Rotliegend and Hauptdolomit reservoirs of the Lower and Upper Permian respectively. The Rotliegend is subdivided into Lower and Upper single porosity reservoirs and contains sweet gas, whereas the Hauptdolomit is fractured and filled with sour gas. Static models with 119 x 74 x 186 and 71 x 39 x 60/60 grid cells have been designed and interactively improved by reservoir data. Based on available fluid and pressure data the 5 pressure independent compartments and reservoir zones have been initialized. The Rotliegend produced compartments represent a GIIP of 0.9 x 109 m³(Vn) and the Hauptdolomit GIIP is estimated at 4.4 x 109 m³(Vn). Subsequently, dynamic simulation models have been performed considering well integrity issues and a secondary dolomite porosity identified. Final history matches have been achieved by the implementation of artificial flow barriers as well as high fracture water saturations taught by the production history.

Summarized the study results confirmed an optimized recovery of both Rütenbrock reservoirs due to the MPT technology. Both the Rotliegend RB_Z16 and the Hauptdolomit RB_Z10a improved considerably in recovery and turned out the efficiency during the use of the Multiphase Pump versus the Conventional Compression period. Innovative approaches have been utilized to match both Rotliegend reservoirs and excelled by the new scientific approach of high fracture water saturations against a low saturation in the dolomitized vugular matrix.

The field Rütenbrock represents the Rotliegend and Hauptdolomit reservoirs of the Lower and Upper Permian respectively. The Rotliegend is subdivided into Lower and Upper single porosity reservoirs and contains sweet gas, whereas the Hauptdolomit is fractured and filled with sour gas. Static models with 119 x 74 x 186 and 71 x 39 x 60/60 grid cells have been designed and interactively improved by reservoir data. Based on available fluid and pressure data the 5 pressure independent compartments and reservoir zones have been initialized. The Rotliegend produced compartments represent a GIIP of 0.9 x 109 m³(Vn) and the Hauptdolomit GIIP is estimated at 4.4 x 109 m³(Vn). Subsequently, dynamic simulation models have been performed considering well integrity issues and a secondary dolomite porosity identified. Final history matches have been achieved by the implementation of artificial flow barriers as well as high fracture water saturations taught by the production history.

Summarized the study results confirmed an optimized recovery of both Rütenbrock reservoirs due to the MPT technology. Both the Rotliegend RB_Z16 and the Hauptdolomit RB_Z10a improved considerably in recovery and turned out the efficiency during the use of the Multiphase Pump versus the Conventional Compression period. Innovative approaches have been utilized to match both Rotliegend reservoirs and excelled by the new scientific approach of high fracture water saturations against a low saturation in the dolomitized vugular matrix.